A gravity flow rack isn't your typical static shelf. It’s a dynamic storage workhorse that uses inclined shelves fitted with rollers or wheels. This smart design lets gravity do the heavy lifting, moving inventory from a loading aisle directly to a picking aisle. The whole system naturally enforces a First In, First Out (FIFO) process, making it an incredibly efficient solution for any warehouse dealing with high turnover goods or products with an expiration date.

Ready to see how this system can streamline your operations? Let's dive in.

How Gravity Flow Racks Work to Optimize Your Warehouse

Imagine a shelving system that uses one of nature's most basic forces, gravity, to deliver products right where your team needs them. That's the elegant idea behind a gravity flow rack. It’s designed to create a smooth, automated flow of inventory that sharpens efficiency and organization from the get go.

The principle is brilliantly simple. Pallets or cartons are loaded onto the high end of a slightly angled rack. From there, they glide gently and safely on rollers or skate wheels toward the lower end, which serves as the picking face.

The Foundation of FIFO Inventory Management

This constant back to front movement is what makes gravity flow racks the gold standard for First In, First Out (FIFO) inventory management. The first pallet you load is always the first one ready to be picked. For businesses handling perishable goods, this isn't just a feature, it's a necessity.

Here’s why automatic FIFO rotation is such a game changer:

- Reduced Spoilage: It ensures your oldest stock moves first, a must have in the food, beverage, and pharmaceutical industries.

- Minimized Obsolescence: Products won't get lost in the back of a rack only to become outdated or expired.

- Improved Quality Control: You can be confident that customers are always receiving products with the longest possible shelf life.

Better yet, by creating separate aisles for loading and picking, gravity flow racks eliminate classic warehouse traffic jams. Forklift operators can replenish stock from one side without ever getting in the way of order pickers on the other. This separation of tasks builds a safer, more organized, and much faster workflow. The value of this approach is why more operations are optimizing warehouse distribution storage space with systems like these.

A Growing Market for Efficiency

The numbers tell the story. The global gravity flow rack market was valued at around USD 2.5 billion in 2023 and is on track to hit USD 4.8 billion by 2032. That's a strong growth rate fueled by a worldwide demand for smarter, more efficient warehouse operations.

This simple yet powerful concept doesn't just protect your inventory; it fundamentally organizes your workflow for major efficiency gains. Understanding how it works is the first step toward building a more productive facility. For more ideas on improving your facility's layout and processes, our guide on warehouse optimization is a great next step.

Unlocking the Benefits of Gravity Flow Racking

Putting in a new racking system is a big deal and a major investment. So, beyond just how they work, let's talk about the tangible returns you can expect from a gravity flow rack. Once you see these core advantages, it becomes clear how this system tackles common warehouse headaches like wasted space, clunky workflows, and spoiled inventory head on.

Maximize Your Storage Density

Warehouse space is expensive real estate, and inefficient racking burns through it. Think about standard selective racks, they demand an aisle for every single row of shelving. A huge chunk of your floor plan ends up being dedicated to nothing more than forklift traffic.

Gravity flow racks completely flip that script. By consolidating loading and picking into their own dedicated aisles, you eliminate all those wasted aisles in between. This high density approach can boost your storage capacity by up to 75% in the exact same footprint. That means storing more product without having to hunt for a bigger building.

Guarantee Automatic FIFO Rotation

For anyone dealing with perishable or date sensitive goods, First In, First Out (FIFO) isn't just a suggestion, it’s crucial for protecting your bottom line. Trying to manage FIFO manually is a recipe for human error, which leads directly to forgotten products, spoilage, and costly write offs.

Gravity flow systems make FIFO completely automatic and foolproof. New stock gets loaded from the back, which pushes the older stock forward to the picking face. Just like that, the first pallet in is always the first pallet out. This built in rotation keeps your inventory fresh and helps you dodge the financial hit from expired products.

Boost Productivity and Throughput

Warehouse efficiency really comes down to throughput, how fast you can move products from the receiving dock to the shipping dock. A gravity flow rack is engineered from the ground up to speed up that process by separating the loading and picking tasks.

Creating dedicated loading and picking aisles establishes a workflow that’s organized and predictable. Forklift operators can replenish inventory from the back without ever getting in the way of the team picking orders from the front. This dramatically cuts down on aisle congestion and makes the whole operation safer.

Facilities that make the switch often see major improvements. In fact, some warehouses report a 30% jump in inventory throughput after implementing these systems. These gains are even more critical in cold storage, where every square foot of efficiently used space counts. You can dig deeper into these market trends and findings.

Enhance Worker Safety and Ergonomics

A messy, disorganized warehouse is an unsafe warehouse. When workers have to reach deep into racks or navigate crowded aisles just to grab a product, the risk of accidents and injuries shoots way up.

Gravity flow systems are inherently safer by design. Products are always presented right at the front of the rack, which gets rid of the need for awkward reaching or stretching. The clean separation of forklift and foot traffic also slashes the chances of collisions. This focus on an organized flow doesn't just improve safety; it makes the job more ergonomic, leading to a more comfortable and productive team.

To really see how these benefits measure up, it helps to put them side by side with other common storage systems.

Storage System Comparison: Gravity Flow vs. Alternatives

This table breaks down the key differences between gravity flow, selective, and drive in racks, giving you a clear picture of where each system shines.

| Feature | Gravity Flow Rack | Selective Pallet Rack | Drive In Rack |

|---|---|---|---|

| Inventory Rotation | Excellent (Automatic FIFO) | Good (Manual FIFO/LIFO) | Poor (LIFO Only) |

| Storage Density | Very High | Low | High |

| Picking Speed | Very Fast | Moderate | Slow |

| SKU Selectivity | Excellent (One SKU per lane) | Excellent (One SKU per pallet position) | Poor (One SKU per bay) |

| Ideal Use Case | High volume, date sensitive products | Low volume, high variety of SKUs | High volume, few SKUs, non perishable |

Each of these advantages translates directly into a more efficient, profitable, and safer operation. If these benefits sound like they line up with your goals, the next step is figuring out how to configure a gravity flow system for your specific needs. We can help with a free layout and design to get you started. Request a Quote today.

Where Gravity Flow Racks Make a Real Difference

Theory is one thing, but seeing how gravity flow racks solve real world problems is where their value truly clicks. Different industries grapple with unique headaches, from battling expiration dates to the relentless pressure of same day shipping. Gravity flow is the elegant solution for a surprising number of these operational pain points.

Thinking through these common scenarios can help you picture how this system might fit into your own facility. The common thread? Anywhere that fast, organized, and dead accurate inventory rotation is non negotiable.

Food and Beverage Distribution

The food and beverage world operates on a ticking clock. Products like dairy, fresh produce, and baked goods have a short fuse. One slip up in stock rotation can mean writing off an entire batch, a costly mistake. The absolute priority is ensuring the oldest products move out first to prevent spoilage.

Gravity flow is tailor made for this. It automates First In, First Out (FIFO) inventory management. When a new pallet of milk is loaded from the back, it automatically queues up behind the older stock, pushing it toward the picking aisle. It's a simple, physics driven process that guarantees freshness, slashes waste, and helps companies stay compliant with food safety regulations. In fact, these systems have been instrumental in modern cold chain logistics, helping achieve a 35% reduction in waste for perishable goods.

Imagine a beverage distributor. They can dedicate gravity flow lanes to each specific drink SKU. This keeps their best sellers constantly available at the picking face, dramatically speeding up how quickly they can build mixed pallet orders for delivery to retail stores.

Pharmaceuticals and Medical Supplies

When you're dealing with pharmaceuticals, inventory management isn't just about the bottom line; it's about patient safety and navigating a maze of regulations. Medications and medical supplies have strict expiration dates, and meticulous lot tracking is mandatory. Shipping an expired product simply isn't an option, making flawless inventory rotation a fundamental requirement.

Gravity flow racks bring the necessary precision to this high stakes environment. Each lane can be assigned to a specific product or lot number, giving operators total visibility and control. As new shipments arrive, they’re loaded from the rear, ensuring that supplies closest to their expiration date are always first in line to be picked. It's a systematic approach that serves as a powerful tool for meeting strict regulatory demands.

E-commerce and Retail Fulfillment

Speed and accuracy are the name of the game in e commerce. Customers now expect their orders to show up almost immediately, which puts incredible strain on fulfillment centers to pick, pack, and ship at a blistering pace. The core challenge is keeping a vast, ever changing number of SKUs organized and ready for lightning fast picking.

This is where gravity flow truly excels. By presenting products right at the picking face, it eliminates the time pickers waste walking and searching for items. Better yet, the separate loading aisle means stockers can replenish inventory without ever getting in the way of the pickers. This creates a smooth, uninterrupted workflow that keeps orders flying out the door, even during the busiest seasons.

High volume distributors in other sectors, like beverage sales, use similar principles to manage their fast moving inventory. You can see how carton flow systems are used for liquor distribution in a related guide.

Manufacturing and Assembly Lines

On the factory floor, a steady, reliable flow of components is the lifeblood of the operation. If the supply of parts to an assembly line sputters, production grinds to a halt, and downtime is expensive. The goal is to create a seamless handoff of materials from the stockroom to the assembly stations.

Gravity flow racks are perfect for "lineside stocking." Bins filled with nuts, bolts, and other small components are loaded into racks from a supply aisle behind the line. They then flow gently down to the workers on the assembly line. This "point of use" delivery system ensures assemblers have exactly what they need within arm's reach, boosting both efficiency and ergonomics.

Critical Design and Configuration Factors

Getting a gravity flow rack system to work perfectly starts long before the first pallet ever rolls down a lane. The design and configuration stage is everything, it's the foundation for a system that’s not just efficient but also safe and perfectly suited to your inventory. If you rush this part, you're setting yourself up for jammed pallets, damaged products, or even a hazardous work environment down the road.

Think of this section as your practical guide. We'll walk through the essential factors our experts consider, so you can have a productive conversation with a designer and be confident that the final system will deliver exactly what you need.

Pallet and Product Specifications

Everything begins with your inventory. The size, weight, and type of pallets or cartons you’re moving are the absolute most important pieces of the puzzle. It sounds obvious, but a system designed for a standard 48" x 40" GMA pallet simply won’t work if you suddenly start feeding it smaller half pallets or heavy duty plastic totes.

Before you go any further, get these details locked down:

- Load Dimensions: What are the exact length, width, and height of a typical loaded pallet or carton?

- Load Weight: What’s the lightest and heaviest a fully loaded unit will be? The range matters.

- Pallet Type and Condition: Are you working with wood, plastic, or metal pallets? Critically, what’s the condition of the bottom boards? A single broken or loose board can snag on a roller and bring everything to a halt.

This information is the bedrock of your design. It directly impacts every other decision, from the type of rollers we specify to the exact width of the flow lanes.

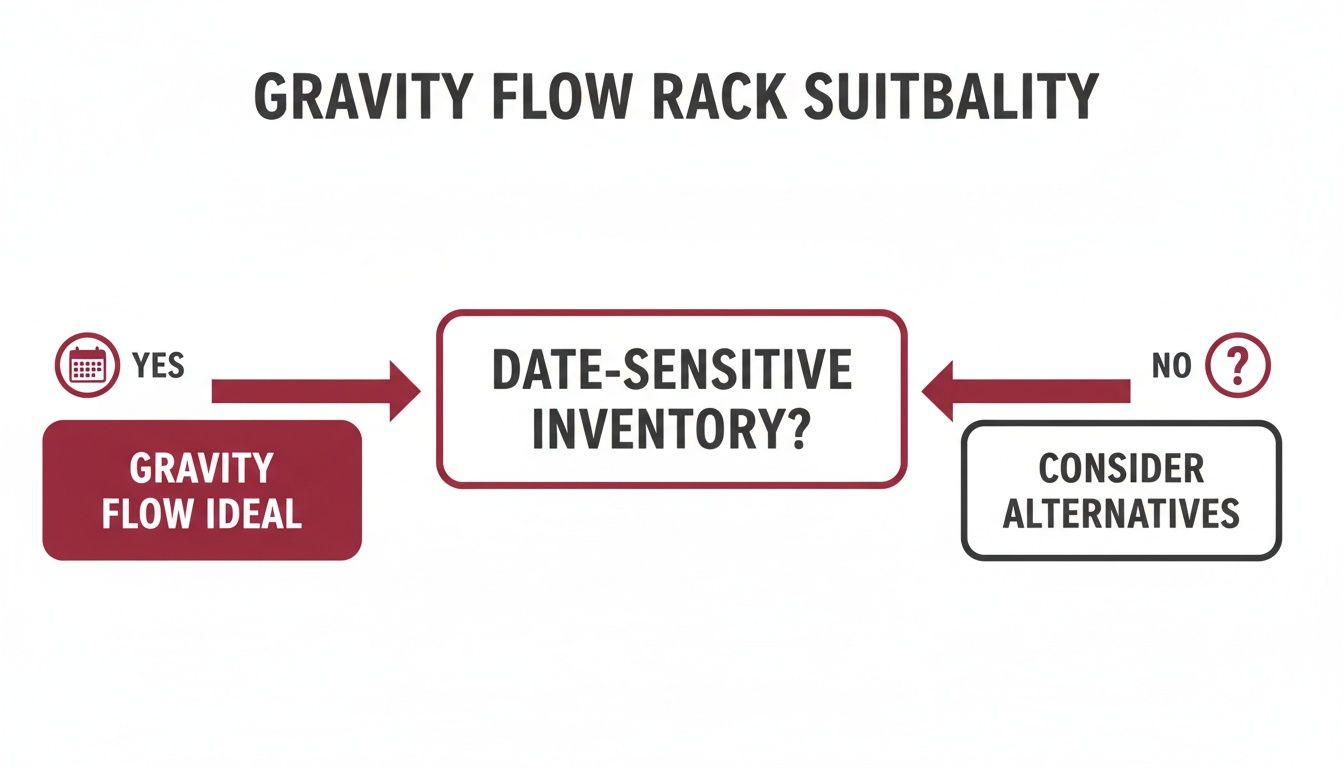

This decision tree shows just how much your inventory's characteristics, like whether it's date sensitive, influence whether a gravity flow rack is the right call for your operation.

As you can see, for any product that needs strict rotation, gravity flow is a natural fit because it physically enforces the FIFO process you need.

Lane Configuration and Layout

Once we know what you're storing, we can figure out how to store it. Designing the lanes is a careful balancing act between cramming in as much product as possible (storage density), ensuring pickers can access the right SKUs, and determining the overall depth of the system.

The lane width needs just enough wiggle room for pallets to flow smoothly without getting hung up. The depth, meaning how many pallets you can fit in a single lane, dictates how much inventory you can buffer. Deeper lanes give you incredible density, but they really only make sense for high volume SKUs that turn over constantly.

For e-commerce supervisors and facility managers, storage density is a game changer. Gravity flow racks can boost storage density by 50% or more compared to selective racks. That means managing two to three times more SKUs without needing to expand your building's footprint, a massive advantage in major U.S. markets where industrial real estate costs have skyrocketed. You can find more on these trends in recent industry reports.

Rollers, Wheels, and Brakes

The components inside the lane are what make the whole system work. The choice between full width rollers and skate wheels isn't arbitrary; it's dictated entirely by your pallets and products.

- Full Width Rollers: These are the workhorses. They're perfect for heavy, consistently sized pallets because they provide even contact and support across the entire pallet base.

- Skate Wheels: Often arranged in a staggered pattern, these are better suited for lighter loads or cartons with smooth, flat bottoms. If you're dealing with smaller, individual items, our guide on carton flow rack systems gets into much more detail.

- Braking Systems: Also known as speed controllers, these are absolutely non negotiable for safety. We install them at specific intervals down the lane to apply just enough friction, ensuring every pallet glides at a controlled, safe speed from the loading aisle to the picking face.

Calculating the Right Slope

Finally, we get to the physics of it all: the angle of the lane. This slope, or pitch, is calculated with precision. It has to be just steep enough for gravity to get things moving and keep them moving, but not so steep that a heavy pallet turns into an uncontrolled projectile.

The perfect slope is a formula based on pallet weight, the type of rollers used, and the total length of the lane. It’s a science, and getting it right is the secret to a system that works flawlessly, every single time.

Navigating these factors might seem overwhelming, but you don't have to figure it out alone. Our team provides free layouts and designs with no obligation, helping you configure the perfect gravity flow system for your products and space. Call (800) 326-4403 to get started.

Why Partner with Material Handling USA?

Picking the right gravity flow rack system is a big decision, but finding the right partner to bring that vision to life is just as crucial. Here at Material Handling USA, we're not just order takers or equipment suppliers. We’re in the business of building solutions, sticking with you from the first sketch to the final bolt being tightened. Our goal is simple: to set up your operation with a system that doesn’t just work, but works wonders for your efficiency and performance.

We get it, budget is always a top concern. That’s why we make sure our pricing on all racking systems is highly competitive. But a great price doesn't mean much if you're stuck waiting on a delivery truck for weeks. We’ve built our reputation on having the fastest shipping and delivery in the industry, so you can get your system up and running without costly delays.

Quality and Expertise You Can Trust

A gravity flow rack isn't just a purchase; it's a long term investment in your warehouse's productivity and safety. That's a responsibility we take seriously, which is why we never cut corners on quality. Every single component is built from high grade materials, engineered to handle the daily grind of a busy industrial environment. This commitment ensures your system will be a reliable workhorse for years to come.

Of course, the best hardware in the world won't do you much good if it isn't designed for your specific operation. This is where our team’s experience really shines.

We believe a perfect solution shouldn't come with a hefty price tag upfront. Our team provides free layouts and designs with no obligation. This lets you see a detailed, professional plan tailored to your unique space, products, and workflow before making any commitment.

Our in house experts will dive deep with you, analyzing your inventory, measuring your facility's footprint, and designing a custom gravity flow rack system that truly maximizes your storage density and kicks your throughput into a higher gear.

Your Next Step to a More Efficient Warehouse

Getting started couldn't be easier. Whether you have a full set of blueprints or just a rough idea scribbled on a notepad, our team is ready to jump in. We're here to answer your questions, offer real world advice, and deliver a solution that fits your operation like a glove. Let us show you what a true partnership with Material Handling USA can do for your warehouse.

Contact Us today to schedule your free, no obligation design consultation. You can also Request a Quote right from our website or give our specialists a call directly at (800) 326-4403.

Frequently Asked Questions

Thinking about gravity flow racks means you're serious about efficiency. It's a big decision, and it's normal to have a few questions before you pull the trigger. We've gathered some of the most common things our customers ask to help you get the clarity you need.

How much maintenance do gravity flow racks require?

Honestly, not much. Gravity flow racks are workhorses designed for durability, so you won't be spending your weekends tinkering with them. The main thing is to do regular visual checks. Look for any damage from forklift bumps, make sure the rollers or wheels are clear of stray shrink wrap or debris, and give everything a quick once over to ensure it's secure.

If a roller does get worn out or damaged, just swap it out. A little preventative care goes a long way, and these systems will easily give you years of hassle free service.

Can we use different pallet sizes in the same system?

Yes, but this is a critical detail to get right from the start. The system has to be designed specifically for the pallets you'll be using. A lane built for a standard 40" x 48" GMA pallet just won't work for a half pallet or something with an unusual footprint. Custom design is non negotiable here.

That’s why our free layout service at Material Handling USA is so valuable. We engineer every detail, lane width, depth, slope, and roller type, to perfectly match your inventory. It takes all the guesswork out of the equation and guarantees your system works flawlessly from day one.

What is the typical ROI on a gravity flow rack system?

The return on investment (ROI) is one of the most compelling reasons to go with gravity flow. Most of our customers see a full payback within 12 to 24 months. That's a pretty quick turnaround, and it comes from a few key areas that hit your bottom line directly.

A strong ROI is usually driven by:

- Significant labor savings: Pickers spend less time traveling and more time picking. It's a huge boost to efficiency.

- Reduced product waste: True First In, First Out (FIFO) rotation means you're not losing inventory to expiration dates.

- Better space utilization: By storing more in your existing footprint, you might be able to put off a costly warehouse expansion.

We can run the numbers with you during a free consultation to map out what the ROI would look like for your specific operation.

Do we need to hire a professional for installation?

For smaller, single level setups, a skilled in house maintenance crew can often handle the assembly just fine. But for anything larger, especially multi level systems, we strongly recommend bringing in professional installers. It’s about safety, proper alignment, and making sure the system performs as it should.

Getting the flow angle just right and ensuring safety features like speed controllers are installed correctly is crucial. It’s not something you want to leave to chance. Material Handling USA has a network of certified installation partners we can connect you with to make sure the job is done right, and more importantly, safely.

Conclusion: Transform Your Warehouse with Gravity Flow

Gravity flow rack systems are more than just storage; they are a strategic investment in warehouse efficiency, safety, and profitability. By automating FIFO rotation, maximizing storage density, and boosting throughput, these systems solve some of the biggest challenges in modern logistics. They reduce waste, improve worker ergonomics, and deliver a rapid return on investment, making them a smart choice for any operation handling high volume, date sensitive goods.

Ready to transform your warehouse efficiency and get more out of every square foot? The expert team at Material Handling USA is here to help you design the perfect gravity flow rack solution for your unique needs. With competitive pricing, the fastest shipping in the industry, and a commitment to quality, we are your trusted partner from concept to completion.

Contact Us for a free, no obligation design consultation and see how a custom solution can elevate your operations.