A pallet rack upright is the vertical steel frame that serves as the backbone of your entire warehouse storage system. It's engineered to bear the full weight of your inventory and provide the fundamental structural integrity for the whole setup. Choosing the right pallet rack upright is one of the most critical decisions you'll make when designing a safe, efficient, and reliable storage solution.

What Is a Pallet Rack Upright and Why It Matters

Think of your pallet racking like a skyscraper. The horizontal beams are the floors, and your inventory is everything inside. The pallet rack uprights are the massive foundational columns holding it all together. If those core supports are weak, incorrectly chosen, or damaged, the entire structure is at risk. That same principle applies to your warehouse storage.

For any facility manager, getting familiar with the basic anatomy of an upright frame is essential. These frames aren't just simple posts; they are complex, engineered assemblies designed for maximum strength and stability. Understanding how these components work together is the first step toward making smart decisions about your system's design and long-term safety.

The Core Components of an Upright Frame

A pallet rack upright isn't a single piece of steel but a pre-welded unit composed of several key parts working in harmony. Each element has a specific job in distributing weight and resisting impacts, ensuring your system stays rigid and stable under thousands of pounds of pressure.

Here's a quick breakdown of what makes up a standard upright frame.

| Component | Function |

|---|---|

| Columns | These are the two vertical steel posts forming the front and back of the frame. They feature the connection points or holes for attaching horizontal beams. |

| Bracing | Steel supports are welded between the columns in horizontal and diagonal patterns. This bracing is crucial for rigidity and preventing the frame from twisting or swaying under load. |

| Footplates | Also called base plates, these steel plates are welded to the bottom of each column. They distribute the load's weight across a wider area of the floor and provide the anchor points for securing the rack to the concrete. |

This combination of components creates a single, incredibly robust frame that's ready for installation. To see how these uprights fit into the bigger picture, you can explore our complete guide to pallet rack and pallet rack systems.

Why the Right Upright Is Non-Negotiable

Picking the right pallet rack upright is about more than just holding pallets—it's a foundational piece of operational safety and efficiency. The wrong choice can lead to catastrophic system failure, destroyed inventory, and most importantly, a hazardous work environment for your team.

A properly specified upright ensures your racking not only meets your current storage needs but also provides a safe, reliable, and scalable foundation for future growth.

The height, depth, and capacity of the upright directly dictate your warehouse layout, aisle widths, and overall storage density. By starting with a solid grasp of this foundational element, you set the stage for a system that's perfectly optimized for your unique operation. If you're not sure where to begin, our team offers free layouts and designs with no obligation.

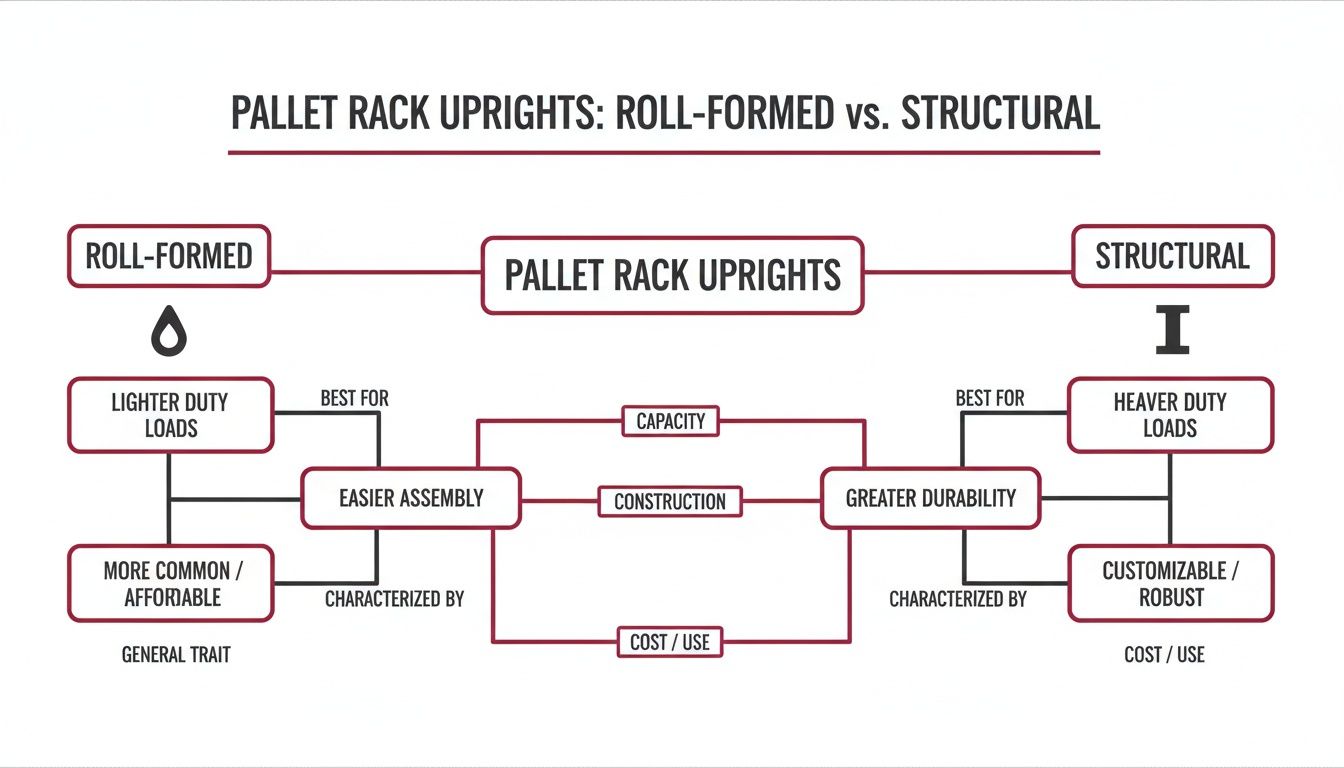

Choosing Between Roll Formed and Structural Uprights

When you're designing a pallet rack system, one of the first big decisions you'll have to make is whether to go with roll formed or structural steel uprights. The way these two types are manufactured creates significant differences in performance, cost, and ideal applications. This decision is fundamental—it shapes your system's durability, flexibility, and overall value for years to come.

Think of it this way: roll formed uprights are the all-stars of most standard warehouses. They're made by cold-rolling steel coils into their final shape. This process makes them light, affordable, and incredibly versatile. It’s also what allows for the teardrop hole pattern, which means you can adjust your beams without special tools.

Structural steel uprights, on the other hand, are the heavyweights. They are forged from hot-rolled C-channel steel, resulting in a frame that is visibly thicker, heavier, and built like a tank. All that extra steel gives them incredible impact resistance, making them the default choice for the toughest warehouse environments.

The Versatility of Roll Formed Uprights

For the vast majority of warehouses, distribution centers, and retail stockrooms, roll formed racking hits the sweet spot between strength, cost, and adaptability. Because they're lighter, they are easier and cheaper to ship and install, which keeps your total project cost down.

The real game-changer is the signature teardrop punch pattern. It gives your team the power to reconfigure beam levels on the fly as your inventory changes, no special tools required. This flexibility is a massive operational advantage.

Of course, there's a trade-off. The thinner steel of a roll formed pallet rack upright is more vulnerable to forklift damage. While they are more than strong enough for their rated loads, they thrive in environments with well-trained operators and predictable pallet traffic.

The market speaks for itself. The roll formed pallet racking systems market was valued at USD 2.62 billion and is projected to hit USD 3.46 billion by 2032. That steady growth is a direct result of the logistics boom, proving just how essential these uprights are to the modern supply chain. You can discover more insights about roll formed pallet racking systems market trends and forecasts.

The Unmatched Strength of Structural Uprights

When your operation can't afford downtime from rack damage, structural steel is the only way to go. It’s built for punishing environments—think freezers, coolers, and high-velocity facilities where forklifts are constantly on the move. The hot-rolled C-channel design can take a hit and keep standing, drastically reducing damage and expensive repairs.

Structural pallet racking is an investment in resilience. It's designed for heavy-duty loads, fast-paced operations, and environments where accidental impacts are a constant risk.

This brute strength makes it the top pick for applications like push-back and drive-in racking, where forklifts actually operate inside the rack structure. The upfront cost is higher, but in a high-throughput facility, the long-term savings from preventing even a single major repair often make it the smarter financial choice.

Comparing Roll Formed vs. Structural Steel

To nail down the right choice, it helps to see them side-by-side. Your decision should be based on your daily operations, your budget, and the reality of your warehouse environment.

| Feature Comparison | Roll Formed Upright | Structural Upright |

|---|---|---|

| Manufacturing Process | Cold rolled steel | Hot rolled C-channel steel |

| Impact Resistance | Good | Excellent |

| Initial Cost | Lower | Higher |

| Adjustability | High (teardrop pattern) | Lower (bolted connections) |

| Best For | General warehousing, retail | Freezers, high-traffic areas |

Ultimately, it’s a classic balance of cost versus performance. For most businesses, our high-quality roll formed uprights deliver an unbeatable combination of value and flexibility.

Need help deciding which pallet rack upright is right for you? Our experts can provide a free, no-obligation layout and quote. Contact Us or call (800) 326-4403 to get started.

How to Accurately Determine Upright Load Capacity

Figuring out the true load capacity of a pallet rack upright isn't as simple as reading a number off a sticker. The upright's real strength is a dynamic value that hinges on the entire system's design—especially the vertical distance between your beams. Getting this right is critical for running a safe and efficient warehouse.

A common mistake is thinking an upright frame has one fixed capacity. The truth is, its ability to hold weight changes dramatically with its setup. The single most important factor is the unsupported span, which is the vertical distance from the floor to the first beam level, or the gap between any two beam levels.

The longer the unsupported span between beams, the lower the overall capacity of the pallet rack upright. Think of it like a support column—the more frequently it's braced horizontally, the more stable and stronger it becomes.

This is why you can't just buy an upright and place beams at random heights. Every unique configuration creates a completely different capacity rating. Overlooking this detail is one of the most common and dangerous mistakes in warehouse setups.

Gathering Your Data for an Accurate Calculation

To find the true capacity of your system, you have to look beyond the upright itself and collect key data about your entire operation. This process makes sure your final design is grounded in real-world needs, not guesswork.

Before you can look at a manufacturer's capacity chart or talk to a design expert, you'll need this information handy:

- Maximum Pallet Weight: What is the absolute heaviest load you will ever place on a single pallet?

- Load Dimensions: You'll need the height, width, and depth of a typical loaded pallet.

- Beam Specifications: Note the length and face size (the height) of your horizontal beams.

- Vertical Beam Spacing: This is the crucial one—the exact measurement of the distance between your beam levels.

Once you have these details, you can start to understand your system's real limits. Our comprehensive guide to pallet rack specifications is a great resource to get familiar with these measurements.

As you can see, while roll-formed uprights are fantastic for flexibility, structural uprights are the heavy-hitters you need for truly demanding applications.

Using Manufacturer Capacity Charts

Every reputable manufacturer provides detailed capacity charts for their pallet rack uprights. These aren't just suggestions; they're the result of rigorous engineering calculations and physical testing. The charts typically cross-reference the specific upright model with the vertical beam spacing to give you a precise capacity rating in pounds.

It is absolutely essential to use the official charts for the exact brand and model of upright you have. Never assume charts from different manufacturers are interchangeable. Steel thickness, column design, and engineering tolerances vary wildly between them. This is a non-negotiable step for building a system that is both safe and compliant.

Don't Guess—Get an Expert on Your Side

Calculating upright capacity involves many variables, and a small mistake can have massive consequences. The safest and most reliable way to design your racking system is to partner with experts who do this every day.

We're here to help. Don't risk the safety of your team or the security of your inventory on a guess. Let our experts provide a precise and reliable capacity calculation you can trust. Request a Quote today.

Getting the Right Fit: Upright Dimensions and System Compatibility

Think of choosing a pallet rack upright like getting a custom suit made—the fit is everything. If you get the dimensions wrong, you're not just looking at an awkward setup; you're creating serious safety risks, wasting valuable storage space, and inviting compliance headaches. Nailing the key measurements—height and depth—is the first step toward a system that works for you, not against you.

These dimensions aren't just numbers on a spec sheet. They directly impact your warehouse layout, from dictating aisle width for your forklifts to determining your overall storage density. They even play a role in fire safety compliance related to flue space. A well-measured system is the foundation for maximizing every square foot of your facility safely and efficiently.

Measuring Upright Height and Depth Correctly

The two most critical dimensions of any upright frame are its height and depth. They seem simple, but measuring them with your specific operation in mind is what makes all the difference.

- Upright Height: This is the total vertical length of the frame. You'll need to consider your ceiling height (leaving 18-24 inches of clearance for sprinkler systems is standard), your forklift's maximum lift height, and the dimensions of your pallet loads.

- Upright Depth: This is the measurement from the front column to the back column. It should be based on the depth of your pallets, ensuring you leave a few inches of overhang on both the front and back for stable support.

As a rule of thumb, your upright depth should be 6 inches less than your pallet's depth. So, for a standard 48-inch deep pallet, a 42-inch deep upright is the go-to choice. This creates a 3-inch overhang on both the front and back beams, which is exactly what you want.

Getting these basic dimensions right from the start saves you from costly layout changes and ensures your system is both practical and safe for daily use.

The Critical Importance of Beam Compatibility

Beyond the physical dimensions, you must ensure your new uprights are compatible with your beams. This is non-negotiable, especially if you're adding to an existing rack system. The connection point where the beam locks into the upright is where the entire load is transferred, so a secure, perfect fit is essential for the system's structural integrity.

The most common connection style in warehouses today is the teardrop hole pattern. Its unique shape makes it easy to install and adjust beams without any tools. But here’s the catch: not all teardrop patterns are created equal. Different manufacturers use slightly different shapes, sizes, and spacing, which can lead to dangerously mismatched connections.

Never mix uprights and beams from different brands without professional verification. A poor fit can create an unstable system that puts both your inventory and your team at severe risk. Always confirm compatibility before you buy.

Your Pre-Purchase Checklist

To help make your buying process as smooth as possible, we put together a simple checklist. If you can gather this information before reaching out, our team can provide a fast, accurate quote and make sure your new uprights are a perfect fit for your operation.

| Upright Selection Checklist | Your Measurement/Requirement |

|---|---|

| Upright Height Needed | |

| Upright Depth Needed | |

| Existing Beam Style (e.g., Teardrop) | |

| Maximum Load Weight Per Pallet | |

| Number of Beam Levels Per Bay | |

| Desired Color |

Having these specs ready helps you make a confident, informed decision. It’s the best way to ensure the pallet rack upright you choose will integrate seamlessly and safely into your warehouse.

Ready to find the perfect fit? Our experts are standing by to help. Request a Quote for a free layout and design, or give us a call at (800) 326-4403.

Best Practices for Installation and Maintenance

A top-quality pallet rack upright is the foundation of a safe storage system, but its long-term integrity hinges on proper installation and consistent maintenance. Think of this as the playbook for protecting your investment, your inventory, and—most importantly—your team. Get these practices right, and your racking will perform safely and reliably for years to come.

The installation process is where safety truly begins. This isn't a step to rush or cut corners on. Every component must be installed according to the manufacturer's exact specifications. That’s the only way to achieve the engineered load capacity and structural stability you're counting on.

Key Steps for a Safe Installation

A successful installation comes down to precision and an eye for detail. From the floor up, each step builds on the last to create a solid, secure structure. Rushing these fundamentals can introduce weaknesses that won’t show themselves until the system is fully loaded and under stress.

Here are the non-negotiable steps for every pallet rack installation:

- Anchoring the Footplates: Every upright footplate must be securely anchored to the concrete floor using the correct size and type of anchor bolts. This is what keeps the entire rack system from tipping or shifting under load or during an impact.

- Ensuring Plumb Uprights: Each pallet rack upright must be perfectly vertical, or "plumb." Using a level is non-negotiable. An upright that leans even slightly—forward, backward, or sideways—won't distribute weight correctly, creating dangerous stress points on the frame and its connections.

- Correct Beam Installation: Beams have to be fully engaged in the upright columns, with their safety clips properly installed. Those clips are a critical failsafe that stops a forklift from accidentally dislodging a beam.

- Verifying Shims: If your floor isn't perfectly even, shims go under the footplates to make the uprights plumb. These must be properly sized and stacked according to industry standards to provide a solid, stable base.

Proper installation is your first line of defense against system failure. Taking the time to get it right ensures your racking is as strong in reality as it is on paper.

Proactive Maintenance and Regular Inspections

Once your system is up, the focus shifts to proactive upkeep. Warehouse environments are tough, and minor damage from daily operations is almost inevitable. The key is to catch small issues before they become major hazards.

A regular inspection routine is the most effective way to stay on top of this. For a deeper look at this topic, check out our guide on how to keep your warehouse racking safe.

Beyond the uprights themselves, think about the bigger picture. We highly recommend optimizing safety and workflow with warehouse floor marking guidelines to create a safer, more efficient environment around your racking system.

Creating a simple checklist for your team can make these inspections fast and effective.

| Weekly Pallet Rack Inspection Checklist | What to Look For | Status (OK/Needs Attention) |

|---|---|---|

| Upright Columns | Dents, twists, or creases from forklift impacts. | |

| Bracing | Bent, broken, or missing horizontal/diagonal braces. | |

| Footplates & Anchors | Loose or missing anchor bolts, corrosion at the base. | |

| Beams & Connectors | Damaged beam faces, missing safety clips. | |

| Overall Condition | Any signs of rust, overloading, or leaning. |

Any item marked "Needs Attention" should be immediately reported, unloaded, and evaluated for repair or replacement. Never ignore damage to a pallet rack upright; its integrity is central to the safety of the entire bay.

Need help assessing your current system or planning a new one? Our experts can provide free layouts and quotes to ensure your setup is safe and efficient from day one. Contact Us or call (800) 326-4403 for a consultation.

Let's Build Your Racking System Together

Choosing the right pallet rack upright is a big decision, but it's not one you have to make alone. You've learned what it takes to select the right type, capacity, and dimensions for a safe and efficient warehouse. Now, let us help you put that knowledge into action.

At Material Handling USA, we are more than just a supplier of quality products at competitive prices. We bring decades of hands-on expertise to the table, and we know that every warehouse has its own unique challenges and goals.

Your Expert Design Partner

Why not take advantage of our free, no-obligation layout and design services? We'll make sure your new system is perfectly suited to your space and workflow. Our specialists will partner with you to create a plan that squeezes every inch of storage out of your facility while keeping safety and workflow front and center. Plus, with the fastest shipping in the industry, we get you what you need, right when you need it.

Investing in the right storage solution is a significant step, and it's a move businesses are making all over the world. The pallet racking market, built on the foundation of quality uprights, was valued at USD 12.23 billion and is expected to hit USD 19.65 billion by 2032. This boom is driven by the explosive growth of e-commerce and manufacturing—all demanding smarter, stronger storage systems. You can discover more about the pallet racking market growth.

Partnering with us means you're not just buying steel; you're investing in a complete solution built for the long haul. We're committed to helping you build a better, more efficient warehouse from the ground up.

Let our team of specialists walk you through the options and design a system that fits your operation perfectly. We are ready to be your ideal partner for your next project.

Ready to start designing your perfect storage system? Request a Quote for a free layout, or give us a call at (800) 326-4403 to talk with a specialist today.

Frequently Asked Questions

When it comes to pallet rack uprights, a few key questions always come up. Getting these right is crucial for safety, system longevity, and making a smart investment. Here are the straightforward answers you need from our team.

Can I Mix Uprights and Beams From Different Brands?

This is a tempting idea to save money, but it's one we strongly advise against. Even if two teardrop patterns look identical, tiny differences in steel thickness, hole punching, and the locking mechanism can create a dangerously weak connection.

Mixing and matching components almost always voids the manufacturer's warranty and can cause issues with safety inspectors. For guaranteed performance and peace of mind, stick with the same brand for both your uprights and beams. If you must mix, have a qualified rack engineer approve it first.

What Is the Difference Between an Upright Frame and a Column?

People often use these terms interchangeably, but they're not the same thing. Think of it like this:

- An upright column is just one of the vertical steel posts with the teardrop holes.

- An upright frame is the complete unit you actually buy. It's made of two upright columns welded together at the factory with a series of horizontal and diagonal steel braces. This truss-like structure gives the frame its strength and rigidity.

When Should I Replace a Damaged Upright Instead of Repairing It?

The official guidance from the Rack Manufacturers Institute (RMI) is clear: any visible damage compromises the upright's capacity. That means any dent, bend, twist, or crease in the steel is a red flag. The moment you spot damage, that entire rack bay needs to be unloaded and cordoned off immediately until a professional can evaluate it.

While there are certified repair kits for very minor, specific types of damage, replacement is almost always the safer and more reliable long-term solution for anything beyond a superficial scratch. When in doubt, err on the side of caution. The cost of a new frame is tiny compared to the potential cost of an accident. Protect your team and replace it.

How Does My First Beam Level Affect Upright Capacity?

This is one of the most overlooked—and most critical—factors in your rack system's strength. The distance from the concrete floor to your very first beam level creates a long, unsupported span on the column. The longer that span, the less weight the entire upright frame can safely hold.

It acts like a leverage point, and too much space dramatically reduces the frame's stability. Every manufacturer provides detailed load capacity charts that show how capacity changes based on this first beam height. Our design experts can help you analyze the numbers to find that sweet spot that maximizes your storage density without compromising safety.

Ready to build a safer, more efficient storage system with the right components? The team at Material Handling USA is here to provide expert guidance and a free, no-obligation layout and design.