Pallet rack dividers are the unsung heroes of warehouse organization. In their simplest form, they are accessories that partition your wide, open pallet rack shelves into smaller, dedicated sections. Think of them as customizable partitions for your racking; they take a single large bay and turn it into multiple, perfectly organized lanes.

This simple addition prevents items from mixing, tipping, or getting lost in the shuffle, making your entire inventory system easier to manage. They're a smart, strategic investment for any warehouse looking to boost efficiency and safety.

What Are Pallet Rack Dividers and How Do They Work?

Picture your pallet rack shelves as a big, undivided drawer in your garage. Without dividers, everything gets jumbled, tools get mixed up, and finding that one specific bolt becomes a frustrating scavenger hunt. That’s exactly what happens on a warehouse shelf. Pallet rack dividers are the fix, acting like partitions to solve these common warehouse headaches.

They work by creating simple physical barriers on a shelf, instantly transforming a vast, chaotic space into smaller, more manageable slots. This straightforward mechanism tackles several critical operational challenges, from jumbled inventory and picking errors to the poor use of valuable vertical space.

Core Functions and Benefits

When you install dividers, you immediately create a more structured and visually clear storage system. This simple change stops valuable products from tipping over and gives your team the ability to quickly and accurately find specific SKUs. At the end of the day, this seemingly minor tool is a major investment in your warehouse's overall performance.

Here are the key operational improvements you'll see:

- Preventing SKU Mixing: By creating distinct lanes, dividers keep different products separate. This is absolutely critical for maintaining inventory accuracy and slashing costly shipping mistakes.

- Improving Product Stability: For items that are not on pallets or are inherently unstable, dividers provide essential side support, stopping them from falling and causing damage or safety hazards.

- Maximizing Vertical Space: They make it possible to efficiently store long or awkwardly shaped items like lumber, pipes, or conduit vertically, which would otherwise be a nightmare to manage.

- Speeding Up Operations: An organized system means your warehouse staff spends less time searching and more time moving. This directly leads to faster put away and retrieval cycles.

A well organized rack system is a safe and profitable system. Dividers are one of the most cost effective ways to improve inventory control, reduce product damage, and increase the speed of your fulfillment operations.

To put it all in perspective, here’s a quick summary of what pallet rack dividers bring to your facility.

Pallet Rack Dividers at a Glance

| Key Function | Primary Benefit for Warehouse Operations |

|---|---|

| Product Segregation | Prevents SKU mixing, improves inventory accuracy, and reduces picking errors. |

| Load Stabilization | Keeps non palletized or unstable items upright, enhancing safety and reducing product damage. |

| Vertical Space Optimization | Allows for efficient vertical storage of long or oddly shaped items like lumber or pipes. |

| Inventory Organization | Creates a clear, visual system for inventory, speeding up put away and retrieval times. |

This table highlights just how versatile and impactful these simple accessories can be for any operation.

Ready to bring order to your warehouse? At Material Handling USA, we offer competitive pricing and the fastest delivery in the industry. For expert guidance on finding the perfect dividers, Request a Quote or call us at (800) 326-4403 for a free, no obligation layout design.

Exploring the Main Types of Pallet Rack Dividers

Not all pallet rack dividers are created equal. Just as you would not use the same tool for every job in the shop, you should not use the same divider for every type of inventory. Getting a handle on the differences between the main styles, Snap In, Hanging, and Bolt On, is the secret to picking the perfect match for your products, racking, and day to day workflow.

Let's break down the mechanics of each type, covering how they install, where they shine, and the distinct advantages they bring to the table. Making the right choice from the get go ensures you get every bit of value from your investment in warehouse organization and safety.

Snap In Dividers

Snap In dividers are the champions of flexibility and speed. True to their name, they are designed for pure simplicity, featuring clips or hooks that attach directly to the grid of your wire decking. No tools, no hardware, no headaches.

This makes them incredibly popular in fast moving environments like e commerce fulfillment centers or 3PL warehouses. When your SKU sizes and inventory profiles seem to change by the hour, your team can reconfigure shelf layouts in minutes. They are the perfect fit for light to medium weight items that need clear separation but not heavy duty structural support.

For operations that demand constant adaptation, the value of a tool free, easily repositionable divider is huge. Snap In dividers let your team adjust storage slots on the fly to match product dimensions, slashing wasted space and boosting picking efficiency.

Hanging Dividers

When you’re dealing with tall or unstable items, hanging dividers provide that critical top down support. Instead of mounting to the shelf surface, they hang from the wire deck or support channels of the shelf level above. This clever design creates a sturdy, full height partition from one beam level to the next.

Picture trying to store tall, narrow boxes that are just waiting to tip over. Hanging dividers act like bookends from the sky, keeping everything upright and secure in its designated lane. This dramatically cuts down on product damage and improves safety by preventing items from falling into adjacent slots or the flue space. They’re a fantastic solution for organizing cartons, apparel boxes, and other lightweight but clumsy products. To see how these dividers work with different surfaces, you can explore the role of pallet rack wire decking in creating a truly versatile and safe storage setup.

Bolt On Dividers

For brute strength and absolute rigidity, Bolt On dividers are the undisputed heavyweights. These beefy dividers are bolted directly to the front and rear beams of your pallet rack, creating an incredibly strong and permanent partition. Once they are in, they are not going to shift, bend, or fail under serious pressure.

This makes them the go to choice for storing heavy, bulky, or long items. You'll often see them organizing lumber, steel pipes, furniture, or heavy industrial components. The secure connection to the rack’s main structural members gives them the strength needed to contain these demanding loads safely. While you lose the flexibility to reposition them easily, their unmatched stability is non negotiable for high capacity, heavy duty storage needs.

Comparison of Pallet Rack Divider Types

To find the right type of pallet rack divider, you really have to look at your specific application. A divider that works wonders in a retail stockroom would be a complete mismatch for a lumber yard.

This table cuts through the noise, breaking down the core differences to help guide your decision.

| Divider Type | Installation Method | Best For | Key Advantage |

|---|---|---|---|

| Snap In Dividers | Clips or snaps directly onto wire decking. | Light to medium weight items, frequent layout changes, e commerce SKUs. | Fast, tool free installation and easy repositioning. |

| Hanging Dividers | Hangs from the wire decking or rack beam above. | Tall, unstable items like boxes or cartons that need top down support. | Excellent vertical support and clear lane definition. |

| Bolt On Dividers | Bolted directly to the pallet rack beams. | Heavy, bulky, or long items like lumber, pipes, or furniture. | Maximum strength, rigidity, and load stability. |

By weighing your inventory and operational needs against these options, you can confidently pick a solution that brings lasting order and efficiency to your warehouse. If you are still not sure which type is right for you, our experts are here to help.

How Dividers Drive Warehouse Efficiency and Safety

Thinking about pallet rack dividers as just a way to tidy up your shelves is missing the bigger picture. This is not about housekeeping; it's a direct investment in the core profitability and safety of your entire operation. A well organized rack system, supported by the right dividers, creates a clear path to a more efficient and secure warehouse.

When you establish defined lanes for each SKU, you start to see a ripple effect across your facility's daily performance. Picking times get faster. Fulfillment errors drop. And you’ll notice a real reduction in labor costs. When your team knows exactly where everything is supposed to be, they spend less time searching and more time on tasks that actually make you money. It transforms your racking from a simple storage box into a high performance system built for speed and accuracy.

Boosting Operational Throughput

The link between organization and speed is undeniable. When products are properly separated, every single step of the inventory management process gets smoother and quicker.

- Accelerated Picking and Putaway: Clear, designated slots eliminate all the guesswork. Staff can locate and store items in a fraction of the time, which means more orders fulfilled per shift. Simple as that.

- Enhanced Inventory Accuracy: By preventing different SKUs from mixing together, dividers make your inventory count far more reliable. This means fewer time sucking cycle counts and less chasing down stock discrepancies.

- Reduced Labor Costs: These efficiency gains translate directly to your bottom line. With faster workflows and fewer mistakes to fix, your labor hours are spent more productively, seriously improving your cost per order.

The data backs this up. For instance, in conventional racking setups, facilities using mesh or wire dividers often report 15% faster inventory cycles. In environments juggling multiple SKUs, divider equipped racks can also reclaim 25-40% more usable storage space.

Creating a Safer Work Environment

Getting faster is only half the story. A safer warehouse is a more productive and reliable one, and pallet rack dividers play a huge role in cutting down on common workplace hazards. Think of them as a proactive tool for protecting your most valuable assets: your people and your products.

Pallet rack dividers are a fundamental safety feature. They prevent products from shifting, leaning, or falling, a common cause of costly inventory damage and, more importantly, serious workplace accidents.

By creating stable, contained storage lanes, dividers reduce the risk of falling objects, which is one of the top causes of injuries in any warehouse. This is especially true for loose, non palletized, or weirdly shaped items that can get unstable in a hurry. The stability that dividers provide helps prevent pallets from tipping, potentially reducing accidents by up to 30% in certain racking systems.

A Holistic Approach to Warehouse Safety

A truly safe facility depends on a layered defense. While dividers manage the risks inside the rack bays, you can't forget about protecting the rack structure itself from equipment collisions. You can learn more about how adding forklift pallet rack protection like column guards and end of aisle protectors creates a truly comprehensive safety system.

While organizing your inventory with dividers is key for operational safety, many facilities also benefit from securing your warehouse facility with professional patrols to deter crime and protect valuable assets. It’s about creating a secure environment both inside and out.

Ultimately, installing pallet rack dividers is far more than just an organizational tweak. It’s a strategic decision that pushes your facility toward being leaner, safer, and more productive, protecting both your people and your bottom line.

Choosing the Right Dividers for Your Application

Picking the wrong pallet rack dividers is more than a small headache; it’s a costly mistake that can snarl your workflow, create safety hazards, and ultimately hit your bottom line. To get it right the first time, you need a smart, methodical approach. This guide will walk you through the critical factors, making sure you match the right divider to your specific racks and inventory.

Think of it like creating a blueprint for your storage bays. Just as an architect needs precise measurements and material specs, you need to nail down your rack dimensions, decking type, and product characteristics to get a perfect fit. Once you have that, you can confidently choose a divider that does not just organize your products but actually makes your whole facility safer and more efficient.

Step 1: Assess Your Racking System

Before you even start thinking about what you're storing, your first move has to be a hard look at your existing pallet rack structure. Dividers are not a one size fits all product; they're designed to integrate with very specific system components. Getting these details right is non negotiable for a secure, functional setup.

Start with these key measurements and identifiers:

- Shelf Depth and Width: Measure the usable depth and width of your shelves. This number directly dictates the length of the dividers you'll need.

- Beam Profile: What kind of beams do you have? Step beams and box beams are common, and the type matters. Bolt on dividers, for example, attach directly to the beams, so compatibility is everything.

- Decking Type: Look at your shelf surface. Is it wire mesh, solid steel, or wood decking? Snap in dividers are made specifically for wire mesh, while other styles might offer more flexibility.

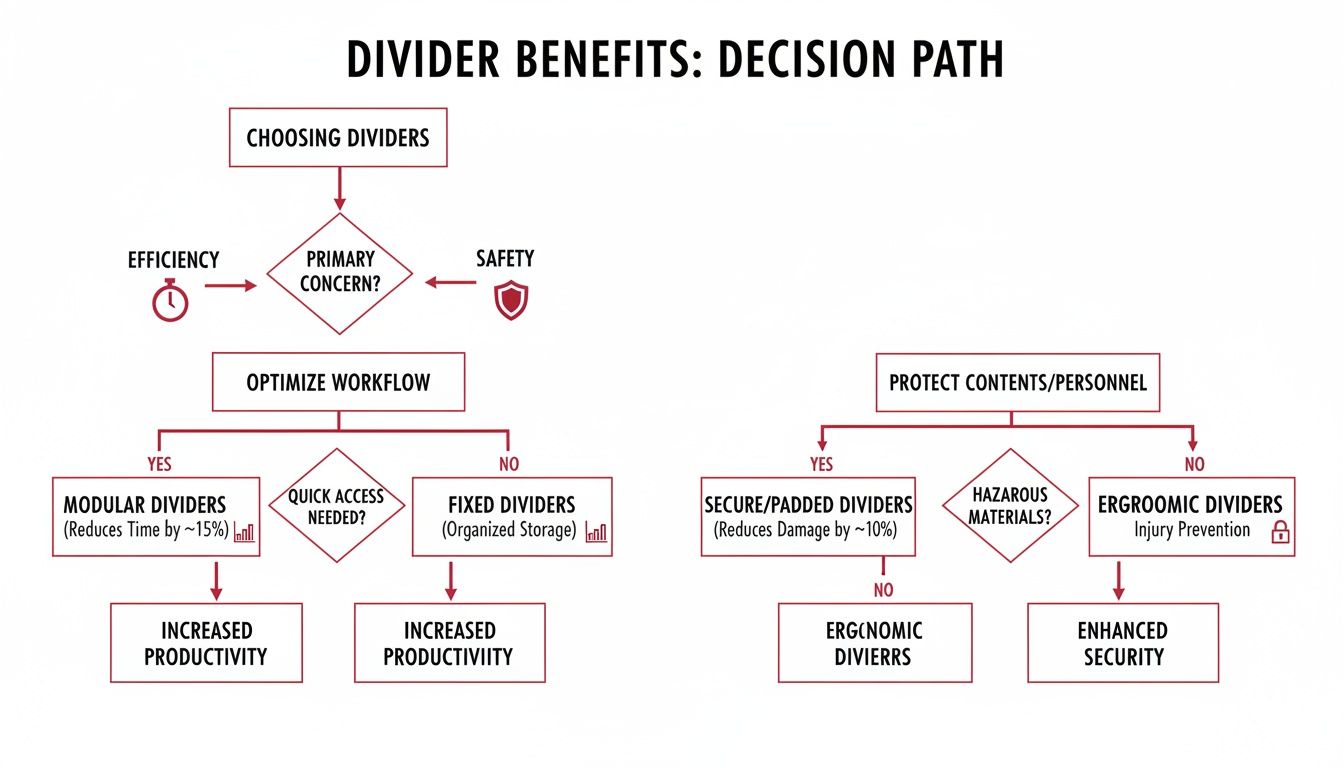

This flowchart lays out the decision making process based on whether your main goal is boosting efficiency or improving safety.

As you can see, different operational priorities point toward different types of dividers to get the job done right.

Step 2: Analyze Your Product Characteristics

With your rack specs in hand, it’s time to focus on the inventory itself. The weight, shape, and stability of your products will determine the type and strength of the divider you need. A divider that works perfectly for lightweight apparel boxes would be a complete failure if you tried to use it for heavy steel pipes.

Ask yourself these questions about your products:

- Weight and Load: What's the total weight of the items that will be pushing against the divider? Heavier loads demand heavy duty, often bolted on solutions.

- Dimensions and Shape: Are your items tall and skinny, long and awkward, or irregularly shaped? A divider's height has to be sufficient to prevent tipping.

- Stability: Can the products stand on their own, or are they prone to shifting, sliding, or rolling? Unstable items need much more substantial separation to stay put.

- Environmental Needs: Does your inventory need airflow, like in a food distribution center? Wire mesh is perfect. Or does it need total containment, like in a secure evidence room? Solid steel is the clear choice.

These dividers, think sturdy mesh panels or solid barriers fitted between uprights, lock pallets in place, cutting sway related damages by 35% in dynamic warehouses. For manufacturing plant facilities teams, this translates to uninterrupted production lines. Data shows U.S. heavy duty racks are growing, with dividers boosting load stability for the 5 to 15 ton capacities that dominate North American demand. You can learn more about pallet racking market trends and their impact on warehouse operations.

Choosing a divider is a balance between your rack system and your inventory. One without the other leads to a poor fit. By matching the divider's capabilities to your specific load requirements, you ensure a safe, efficient, and long lasting storage solution.

Step 3: Get Expert Guidance

Trying to juggle all these variables is tricky, and frankly, guesswork can lead to expensive errors. Why take that risk? The surest way to eliminate uncertainty and guarantee a perfect fit is to bring in an expert.

At Material Handling USA, we offer free layout and design services with no obligation. Our specialists live and breathe this stuff. They’ll help you analyze your racking and inventory to select the ideal pallet rack dividers for your unique operation. We make sure you get a solution that maximizes your space, improves your workflow, and fits your budget.

Don't leave your warehouse optimization to chance. Contact Us today for a free quote and a professional design consultation.

Proper Installation and Usage Best Practices

Getting the most out of your pallet rack dividers really boils down to two things: installing them correctly from the start and using them safely every single day. When you follow the right procedures, your dividers will do exactly what they're supposed to, creating a warehouse that's not just organized, but fundamentally safer. This guide will walk you through the practical, no nonsense steps for both installation and daily operations.

Think of proper setup as more than just slotting dividers into place; it’s an investment in protecting your team and your inventory. Before you even think about installation, basic safety protocols like wearing gloves and making sure the bays are completely empty are absolutely non negotiable.

Installing Different Divider Types

Every divider type has its own way of locking into place. Getting it right is key to a secure fit and making sure they hold up over time.

- Snap-In Dividers: These are the simplest of the bunch. Just line up the clips on the bottom with the wire mesh grid of your decking. Then, press down firmly until you hear a solid "snap." No tools needed, which means you can adjust your layout on the fly.

- Hanging Dividers: For these, you’ll position the divider so its hooks sit securely over the wire strands or the support channel of the shelf above it. Give it a gentle wiggle to make sure it’s hanging straight and stable before you start loading products into the new lanes.

- Bolt-On Dividers: This is where you'll need to grab a wrench. Position the divider against the front and back beams, lining up the mounting holes. Slide the bolts through and tighten the nuts until there’s zero wobble or play.

Daily Operations and Safety Protocols

Once your pallet rack dividers are in, sticking to best practices during day to day use is what keeps everything running smoothly and safely. This covers everything from how your team loads products to your inspection routine.

Loading inventory the right way is your first line of defense. Always place items so the weight is spread evenly inside the lane, and never let product lean heavily against one side of a divider. You’ll also want your team to do regular visual checks for any signs of bending, cracking, or other damage that could weaken the divider.

Crucial Safety Reminder: Pallet rack dividers are designed for one job: organization. They do not add any strength or increase the weight capacity of your pallet rack shelves or beams. Always respect the manufacturer's load limits to prevent a dangerous rack failure.

With e commerce growing, smart warehouse practices are more critical than ever. In busy retail stockrooms, dividers prevent cross contamination of goods, which can slash returns by 20%. In a broader sense, using dividers correctly can reduce forklift strikes by 32% and, in high security areas like evidence rooms, cut unauthorized access risks by 27%. You can find more insights on the pallet racking market at Market Research Future.

If you want expert help to make sure your system is installed right and used safely, Request a Quote from our specialists. We offer free layouts and designs to help you optimize your setup from day one.

Conclusion: Let Us Help You Get Organized

You’ve seen what pallet rack dividers can do. They’re a straightforward, powerful way to bring order, safety, and a serious dose of efficiency to your warehouse floor. Now that you know how they work, the types available, and what to look for, the next step is putting that knowledge into action. It's time to transform those cluttered bays from a logistical headache into a high performance asset.

At Material Handling USA, we make that step easy. We're committed to providing top quality products at prices that make sense, all backed by the fastest shipping and delivery in the industry. Our whole goal is to get your facility the solutions it needs, without the frustratingly long waits.

Your Partner in Warehouse Optimization

Look, we're more than just a supplier of steel and wire. We see ourselves as your partner in building a smarter, more scalable operation. We have been in this business long enough to know that every warehouse has its own unique set of problems, which is why we offer support that goes way beyond just selling you a product. Our team is here to make sure you find the perfect fit for your specific inventory and racking, maximizing every dollar you invest.

Choosing the right storage solution is not just about buying hardware; it’s a critical operational decision. We believe in empowering our clients with not only the best products but also the expert guidance needed to make them work effectively for the long haul.

Here's how we help:

- Expert Guidance: Our specialists live and breathe this stuff. They’re ready to walk you through the options and make sure you select the ideal dividers for your inventory and existing rack system.

- Free, No Obligation Quotes: Get clear, upfront pricing with zero strings attached. We provide detailed quotes so you know exactly what to expect and can budget effectively.

- Complimentary Layouts and Designs: Not sure how to best configure your space? We offer professional design services to help you create an efficient and compliant warehouse layout that actually works.

Take the Next Step Today

Whether you're ready to order right now or you still need some expert advice to nail down your plan, we have got you covered. For those who know exactly what they need, our online store is stocked and ready to go.

If your project is a bit more complex, our team is standing by. We can help you explore your options and provide a detailed plan with our pallet rack design services.

Ready to upgrade your warehouse? Request a Quote for a custom solution, or give our team a call at (800) 326-4403 to talk through your project. Let's work together to build a safer, more organized, and more productive facility.

Frequently Asked Questions About Pallet Rack Dividers

Alright, you've seen what pallet rack dividers can do, but a few practical questions might still be bouncing around. That’s perfectly normal. Getting straight answers is the only way to feel confident you're making the right call for your warehouse.

Let's clear up some of the most common questions we get from managers and buyers every day. The goal here is to tackle those final details so you can move forward with a solid plan.

Will these dividers fit any kind of rack?

While dividers are incredibly versatile, they are not a one size fits all solution. Compatibility almost always comes down to what kind of decking you have on your beams.

Snap in dividers, for example, are made specifically for wire mesh decking. They need to match the grid pattern perfectly to lock in place and do their job. Bolt on dividers, on the other hand, attach right to the beams, which gives them the flexibility to work with wire, solid steel, or even wood decking. Hanging dividers also play nice with most wire decking styles.

Don't guess, check. It's crucial to confirm your rack's specs before you order. A mismatch can lead to a wobbly, unsafe setup that's more of a hazard than a help.

The best way to guarantee a perfect fit? Give our specialists a call. A quick, free consultation can make sure you get the exact divider for the system you already have.

How do I figure out the right divider height?

Choosing the right height is all about the inventory you're storing. The main job of the divider is to keep your products from leaning or toppling over into the next slot.

A good rule of thumb is to pick a divider that's at least two thirds the height of your tallest item. If you're dealing with unstable products like cylinders or long, skinny boxes, you'll want a divider that's nearly the full height of the bay opening. That'll give you the best possible support and containment. If your product mix is constantly changing, just go with the taller dividers, you'll thank yourself later.

Can I use dividers to hold more weight on my shelves?

No, and this is a safety point we can't stress enough. Pallet rack dividers are for organization, not for structural support. They separate products, period.

Dividers do not, under any circumstances, increase the weight capacity of your beams or decking. Always stick to the load capacity ratings provided by your rack's manufacturer. Overloading a shelf because you think dividers add strength is a recipe for a catastrophic failure, putting your people and your inventory at serious risk.

What's the difference between front to back and left to right dividers?

These terms just describe how the dividers are oriented on the shelf. The right choice really depends on how you pick and manage your inventory.

-

Front to Back Dividers: These run from the aisle to the back of the rack, creating long, deep lanes. This setup is great for storing different lots of the same SKU or for managing inventory with a first in, first out (FIFO) system.

-

Left to Right Dividers: Sometimes called side to side dividers, these run parallel to the beams. They create individual slots across the width of the shelf. This is the most common setup for separating different SKUs so pickers can easily grab them from the aisle.

At Material Handling USA, we know every warehouse has its own set of challenges. If you have more questions or need a hand designing the perfect storage layout, our team is ready to help with expert advice, plus free layouts and designs.

Request a Quote