Get a Project Quote

Ready to start? Provide your project details, and our team will deliver a comprehensive quote.

Home | Warehouse Design | WMS-Integrated Warehouse Design: Where Data Defines Your Layout

We bridge the gap between your operational data (WMS/WES) and your physical space for a truly optimized workflow.

Your Warehouse Management System (WMS) is the brain of your operation, holding a wealth of data on every aspect of your inventory and order flow. Yet, for many businesses, a critical disconnect exists between this powerful digital intelligence and the physical reality of the warehouse floor. The layout of racks, aisles, and workstations is often designed based on static assumptions, not the dynamic, real-time data your systems collect every second. This gap creates hidden inefficiencies, forces your WMS to work around a suboptimal environment, and limits your operational potential.

A truly modern warehouse does not treat its physical layout and its digital systems as separate entities. It integrates them. WMS-integrated design is a data-first approach that uses the intelligence from your WMS, WES, and other systems to architect a physical space that is a perfect reflection of your operational needs. It’s about letting SKU velocity data determine slotting locations, order profiles shape picking paths, and throughput analytics define forward-pick areas.

This methodology transforms your warehouse from a simple container into a dynamic, responsive ecosystem where the physical and digital work in harmony. It ensures that your investment in sophisticated software is fully realized, creating a seamless flow of goods that is directed by data and executed with maximum efficiency in a purpose-built environment.

Ready to start? Provide your project details, and our team will deliver a comprehensive quote.

In a traditional design process, the physical layout is established first, and the WMS is configured to operate within its constraints. A data-first approach reverses this logic. We begin by analyzing the rich data within your WMS and WES to understand the true behavior of your operation. This data—on SKU velocity, order profiles, inventory seasonality, and picking patterns—becomes the blueprint for the physical design.

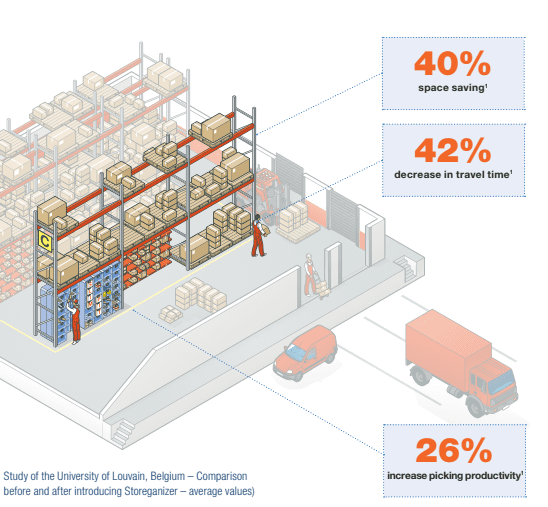

The core principle is to create a layout that makes the most efficient processes possible. For example, by analyzing your sales data, we identify your fastest-moving SKUs and design forward-picking zones and pick modules that place these items in the most accessible locations, minimizing travel time for your team. We study order profiles to understand which items are frequently ordered together and co-locate them to streamline multi-line order fulfillment. This is the foundation of a truly intelligent warehouse design.

This process ensures that your physical infrastructure directly supports the logic of your WMS. Instead of your system calculating the “least bad” picking path in a poorly designed space, the space itself is engineered to facilitate the ideal path. This synergy is a critical component of warehouse optimization and is detailed in our step-by-step guide to designing an efficient warehouse layout.

Have questions? Schedule a no-obligation consultation with a modular construction expert.

A data-driven design does more than just place racks efficiently; it creates an environment where every physical task is synchronized with your digital systems. The goal is to eliminate friction between the instructions from the WMS and the actions of your team and equipment on the floor. This requires a holistic view that considers everything from aisle width and rack configuration to the placement of packing stations and shipping docks.

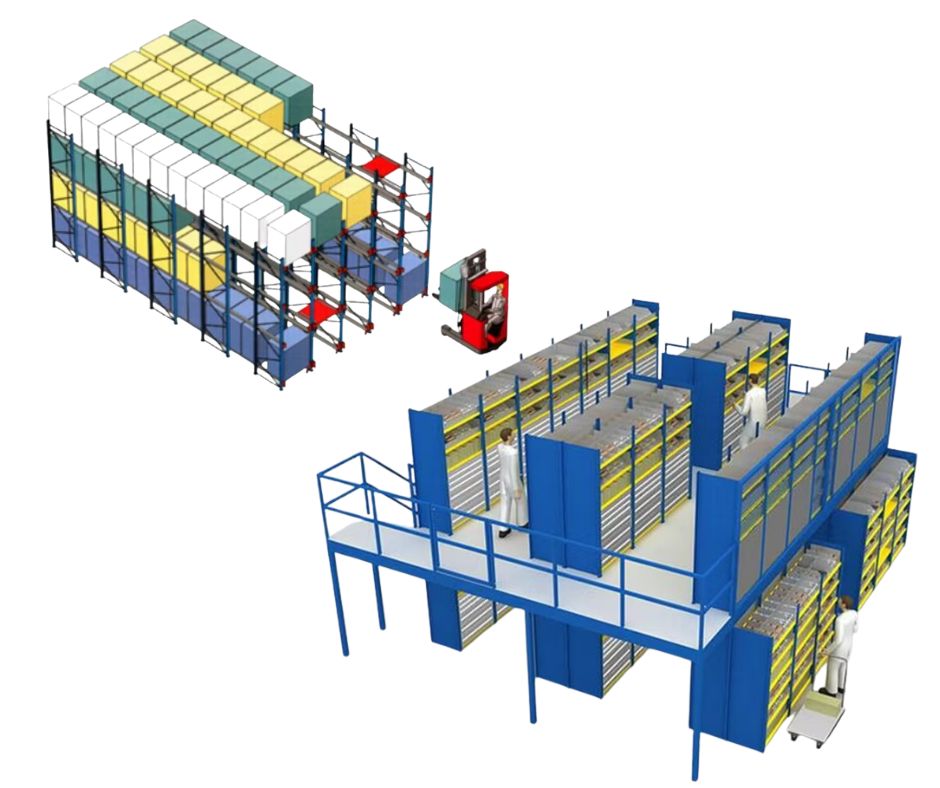

For instance, if your WMS supports batch picking or zone picking, the physical layout must be divided into logical zones that align with that software logic. If you use directed putaway, the storage locations must be clearly labeled and easily accessible, with pallet racking and tailored shelving solutions that match the inventory profiles managed by the system. The choice of storage media, whether it’s standard racking for diverse goods or specialized racks for items like pool and hot tub supplies, is a decision informed by WMS data.

This synchronization extends to automation. When you implement Automated Storage and Retrieval Systems (ASRS), the physical integration with your conveyor systems and workstations is critical. The entire system is part of a full warehouse design solution where the WES can direct both automated equipment and human workers in a coordinated flow, essential for achieving warehouse automation for next-day delivery.

Whether you need to outfit a new facility or upgrade your existing storage, we can provide a competitive quote for high-quality racking and shelving solutions.

Technology evolves rapidly. A warehouse designed today must be ready for the systems of tomorrow. A WMS-integrated design approach is inherently future-proof because it creates a flexible, scalable physical infrastructure that can adapt to new software, hardware, and automation. This involves making smart decisions about everything from floor slab specifications to power distribution and network connectivity.

A key consideration is creating a facility that is ready for robotics and other forms of automation. This means ensuring floor flatness meets the specifications for autonomous mobile robots (AMRs), that the racking layout provides clear paths for navigation, and that your Wi-Fi network is robust enough to handle the data load from dozens or hundreds of connected devices. The structural integrity of your storage is also critical. Following essential pallet rack safety guidelinesand using tools like warehouse rack protectors ensures your infrastructure remains sound as your operations scale.

This forward-looking approach also considers safety and security as integral to the system. Proper warehouse fire safetymeasures are designed in from the start, and solutions like security cages can be integrated to work with your WMS for controlled access to high-value inventory. By building a facility that is physically and digitally robust, you ensure your investment is worthy for the long term.

Learn more about how we design and implement the physical infrastructure required to support advanced warehouse automation.

For a data-focused leader, integrating your physical and digital infrastructure is not just an operational improvement; it’s a strategic IT decision that delivers powerful benefits.

Ensures your significant investment in WMS/WES software delivers its full potential by creating a physical environment that allows the system to operate at peak efficiency.

A logical, well-organized physical space reduces putaway errors, picking mistakes, and lost inventory, leading to more accurate data within your systems.

Reduces the computational load on your WMS by simplifying routing and decision-making. When the layout is intuitive, the system works less to find efficient paths.

A system-ready design makes it faster and easier to deploy new technologies, from barcode scanners and voice systems to robotics and ASRS, reducing integration costs and timelines.

When the physical layout mirrors the logical structure in your WMS, it becomes easier for managers to visualize workflows, identify bottlenecks, and make data-driven decisions. This helps to enhance warehouse efficiency.

Absolutely. We specialize in creating custom warehouse design and layout services that are tailored to the specific logic and capabilities of your unique WMS environment.

We typically analyze SKU master files, historical order data, inventory turn rates, and receiving/shipping logs. All data is handled confidentially and can be anonymized.

This methodology is effective for both. We can design a complete layout for a new building or re-engineer the layout of an existing facility to better align with your WMS data, significantly improving productivity.

Safety is a non-negotiable part of our process. Every design adheres to strict safety standards, from keeping warehouse racking safe to implementing comprehensive fire safety and personnel protection measures. We help you improve warehouse safety and productivity in tandem.

The timeline varies with the project’s complexity. A data analysis and conceptual design phase can take a few weeks, while a full physical implementation can range from weeks to months. We provide a detailed project plan with clear milestones upfront.