Standard Stretch Wrap Machine

Robotic Stretch Wrap Machine

Orbital Stretch Wrap Machine

Home | Stretch Wrap Machines for Pallets

Are You Ready to Transform Your Pallet Wrapping Process?

Are you still stretch wrapping pallets by hand? It’s time to upgrade to a more efficient method. Stretch Wrap Machines can boost your efficiency, increase loads per hour, and maximize operational uptime. Whether you operate a small warehouse or a large distribution center, these machines can significantly streamline your process and save valuable time.

Contact us now to receive a personalized quote for your stretch wrap machine needs.

Economical and semi-automatic, these turntable wrapping machines are reliable, safe, and easy to use. They function by spinning the pallet around like a record player, with the wrapping machine remaining stationary.

Fully automatic, these stretch wrappers completely automate the wrapping process, offering significant savings, high performance, and enhanced safety.

Ideal for wrapping oddly shaped or oversized loads, these horizontal stretch wrappers provide reliable and resilient ways to ship products with minimal manual labor.

Cost Savings

Using stretch wrap machines can lead to significant cost savings. By optimizing film usage and reducing labor costs, these machines pay for themselves over time.

Enhanced Productivity

With the ability to wrap more pallets per hour, your overall productivity will see a substantial increase. This means quicker turnaround times and more efficient operations.

Better Load Stability

Stretch wrap machines ensure consistent wrapping, which enhances load stability. This reduces the risk of product damage during transport, ensuring your goods reach their destination safely.

Improved Employee Safety

With built-in safety features such as emergency stop buttons and ergonomic designs, these machines minimize the risk of injury, ensuring a safer workplace.

Discover the features and benefits of our range of stretch wrap machines.

Understanding how stretch wrap machines operate can help you maximize their benefits.

Over 30 Years Of Experience

We design and install the right storage solutions for your specific needs

Custom

Options

We offer a range of customizable options to meet your unique needs

Customer Satisfaction

We are committed to excellent service and support, ensuring satisfaction with every purchase

Competitive Pricing

We offers competitive pricing, making it easy to find a solution that fits any budget

Tate W. Curtis

Space Coordinator, United States Department of Agriculture

“ They always available for meetings and questions, firsts, in figuring out what system would work best for our needs then by assessinh how much shelving space would be required for our existing as well as future needs, and , finally, by insuring the timely delivery and quality installation of the product. ”

Sharon L. Hancey

First District TCE of Administrative Office of the Courts

“ They were extremely attentive in assessing our needs in Logan. They provided several plans to show us our shelving options. ”

Julie Froff

Assistant Clerck of

Third District Court

“ We have been using the system now for about six moths and are happy to report that it has been a wonderful addition to our office. It is easy to operate and keeps our filing area neat and organized, and most importanly, providers us with unlemited space for growth at this time. We are completely satisfied with your product. ”

Lila Abersold

Visual Arts Coorndinator of Utah Arts Council

“ The track and system Material Handling USA recently installed is working very well Your isntallation people were able to adjust the tracks on the uneven floor in our storage space. ”

Nancy Herd

Human Resources Manager of Ray Quinney & Nebeker

“ Thank you a million times for the these killer Jazz tickets! I am just so excited to go and rub shoulders with every other "pretentious" person in Material Handling USA! How Awesome! ”

Stretch wrap machines automate the process of wrapping stretch film around pallets, ensuring secure and stable loads for transport.

They increase the number of pallets wrapped per hour, reduce film usage, and minimize manual labor, leading to overall efficiency improvements.

Common safety features include emergency stop buttons, ergonomic film loading, and low voltage operation to reduce shock hazards.

Yes, many machines offer adjustable settings and can wrap various pallet sizes and shapes.

Consider your pallet dimensions, weights, and daily wrapping volume. Also, assess the machine’s features and safety options.

Stretch wrap machines are compatible with various machine-grade films, including standard, pre-stretched, and oriented films.

Yes, fully automatic machines, like the robotic stretch wrap machine, offer high efficiency and minimal manual intervention.

Orbital stretch wrap machines wrap pallets horizontally by orbiting around them, ideal for oddly shaped or oversized loads.

What are the cost benefits of using stretch wrap machines?

Contact us with your pallet dimensions, weights, and wrapping volume to receive a tailored quote for the best machine for your needs.

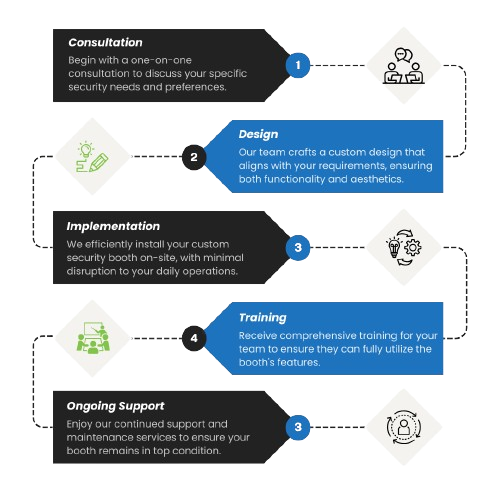

We are committed to providing customized design solutions. Our expert team is ready to meet with you on Zoom, enabling real-time, interactive discussions about your specific needs. Using screen sharing, we can walk you through our proposals, ensuring efficient design planning and immediate feedback. Let’s create the perfect solutions together.