Get a Project Quote

Ready to start? Provide your project details, and our team will deliver a comprehensive quote.

We design high-velocity fulfillment centers optimized for small-order, high-SKU environments to minimize pick-to-pack times.

The world of e-commerce moves at the speed of a click. Customer expectations for rapid, accurate, and free shipping have transformed the warehouse from a simple storage facility into the heart of the customer experience. A traditional warehouse, designed for bulk pallet-in/pallet-out movements, is fundamentally unequipped to handle the complex demands of direct-to-consumer fulfillment. The unique challenge of e-commerce—processing thousands of small, multi-line orders with a vast number of SKUs—requires a specialized approach to design.

An e-commerce fulfillment center is an entirely different ecosystem. Success is measured in seconds, and efficiency is defined by the time it takes to get an order from picked to packed to shipped. A suboptimal layout creates bottlenecks, increases labor costs, and leads to picking errors that erode customer trust and profitability. The only way to win is with a facility that is purpose-built for the speed and precision that modern e-commerce demands.

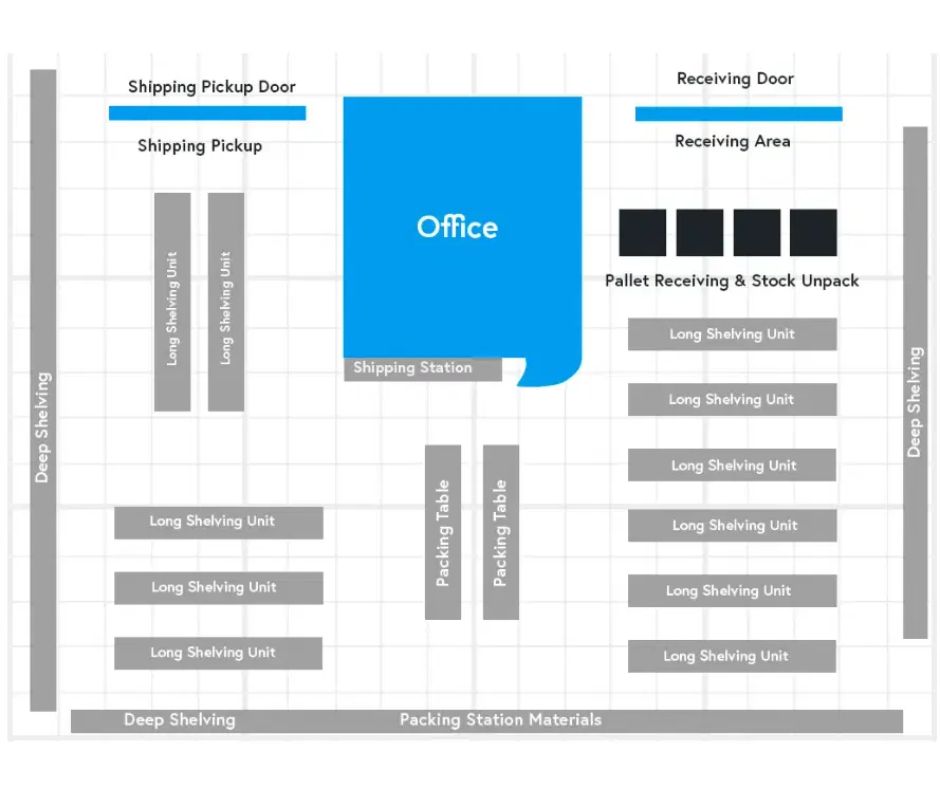

We specialize in designing high-velocity fulfillment centers that are engineered to thrive in high-SKU, small-order environments. By focusing on a data-driven warehouse optimization strategy, we create layouts that streamline every step of the process, from receiving and putaway to picking, packing, and shipping. This is about more than just arranging racks; it’s about creating a cohesive system where people, processes, and technology work together to achieve flawless fulfillment.

Ready to start? Provide your project details, and our team will deliver a comprehensive quote.

In e-commerce, the single greatest expense and time sink is the picking process. A picker walking unnecessary steps through a disorganized warehouse is a direct drain on your bottom line. The core of an effective e-commerce layout is the relentless optimization of the pick path to minimize travel time. This requires a design that is intelligent, data-driven, and flexible.

The process begins with a deep analysis of your sales data to understand SKU velocity. Your fastest-moving products (the “A” items) must be placed in the most accessible, forward-picking locations to ensure they can be retrieved with minimal effort. Slower-moving items can be stored in less accessible areas. This slotting strategy, detailed in our step-by-step guide to designing an efficient warehouse layout, is fundamental to reducing travel. We design zones, pick modules, and forward-pick areas that are a direct reflection of your sales patterns, creating an intelligent warehouse design.

Furthermore, the choice of picking methodology—such as batch picking, zone picking, or wave picking—directly influences the physical layout. The facility must be designed to support your chosen strategy. This includes creating appropriately sized zones, ensuring smooth flow between them, and integrating conveyor systems or other transport mechanisms. The goal is to create a system where pickers are always moving purposefully, guided by a layout that makes their work as efficient as possible.

Have questions? Schedule a no-obligation consultation with a modular construction expert.

Unlike traditional warehouses that handle uniform pallets, e-commerce fulfillment centers must manage a massive and diverse range of SKUs, from tiny accessories to bulky items. The storage media must be just as diverse and flexible. Using standard pallet racking for everything is inefficient and wastes a tremendous amount of space. A successful design employs a variety of storage solutions tailored to the inventory.

For small, individual items, high-density warehouse shelving and racks or carton flow systems provide dense, organized, and easily accessible storage. For items with moderate turnover, standard pallet racking may be appropriate. The key is to match the storage solution to the product’s size, weight, and velocity. These tailored shelving solutions are a critical component of maximizing your storage footprint and keeping your inventory organized.

Automation plays a significant role here as well. Automated Storage and Retrieval Systems (ASRS) are ideal for managing high-SKU environments with exceptional density and accuracy. These goods-to-person systems bring the required items directly to a picker, virtually eliminating travel time. Integrating such technology is a core part of a full warehouse design solution and is essential for any operation aiming for warehouse automation for next-day-delivery.

Whether you need to outfit a new facility or upgrade your existing storage, we can provide a competitive quote for high-quality racking and shelving solutions.

The packing station is the final and most critical touchpoint before an order leaves your facility. It’s your last opportunity to ensure accuracy, present your brand professionally, and create a positive customer experience. An inefficient or poorly designed packing area can become a major bottleneck, undoing all the efficiency gains from an optimized picking process.

An ergonomic and well-equipped packing station is essential. Stations should be designed to minimize reaching and bending, with all necessary supplies—boxes, tape, dunnage, and shipping labels—within arm’s reach. Integrating scales, scanners, and dimensioners directly into the station streamlines the process and reduces errors. This focus on ergonomics helps to improve warehouse safety and productivity.

The layout of the entire packing and shipping area must be designed for a smooth, linear flow. Picked orders should arrive at one end, move seamlessly through the packing and quality control process, and exit to the shipping area without any cross-traffic or backtracking. This requires careful planning of conveyor systems, sorting mechanisms, and the staging areas for various carriers. A well-designed pack-out area is a vital tool for warehouse organization and safety.

Let us show you how to design packing stations that are faster, more accurate, and safer for your employees.

Investing in a fulfillment center designed specifically for e-commerce is not a luxury; it’s a requirement for survival and growth in a competitive market.

An optimized layout that minimizes travel and streamlines workflows allows you to process more orders per hour with the same number of staff.

A logical flow, organized storage, and ergonomic workstations reduce the likelihood of human error, leading to fewer mis-picks and happier customers.

By making your team more efficient, you reduce your cost-per-order and can better manage labor expenses, especially during peak seasons.

Using the right mix of storage solutions for your high-SKU inventory allows you to store more products in your existing footprint, delaying or avoiding costly expansion.

We design flexible facilities that can adapt to your changing SKU profiles, order volumes, and the integration of new automation, ensuring your investment is worthy for the long term.

We design flexible layouts with scalable processes. This includes creating dedicated zones for seasonal or high-velocity products that can be activated during peak times and designing workflows that can be easily scaled up or down with temporary labor.

Yes. Our warehouse design and layout services include retrofitting existing spaces to accommodate automation, ensuring the physical infrastructure supports the technology.

While there are many important metrics, cost-per-order and order accuracy are two of the most critical. Our designs are focused on improving both by increasing efficiency and reducing errors.

Safety is integral to our design process. We adhere to all safety standards, from keeping warehouse racking safe with proper protection and inspections to ensuring robust warehouse fire safety and clear traffic management.

We can integrate secure storage solutions, such as security cages or other controlled-access areas, directly into the fulfillment workflow to protect your valuable inventory without slowing down the process.